Not all dehydration systems are created equal—especially in the liquefied natural gas (LNG) industry, where performance standards are among the most unforgiving. Whether it’s upstream gas collection, midstream transport, or downstream processing, a natural gas dehydration unit is critical to keeping moisture out of the equation and operations running without interruption.

The Core Job of a Natural Gas Dehydration Unit

Natural gas must be dried before it can be transported, processed, or liquefied. In LNG applications, this is a matter of chemistry and safety. Moisture in natural gas crystallizes into ice or hydrates at cryogenic temperatures, which can cause line blockages, equipment failures, and serious operational hazards. A proper dehydration unit removes that risk.

These systems are designed to eliminate water vapor through various methods, but the two most common are:

- Pressure Swing Adsorption (PSA): Often found in twin-tower regenerative dryers, this method uses desiccants like activated alumina to adsorb moisture. One tower dries the gas while the other regenerates.

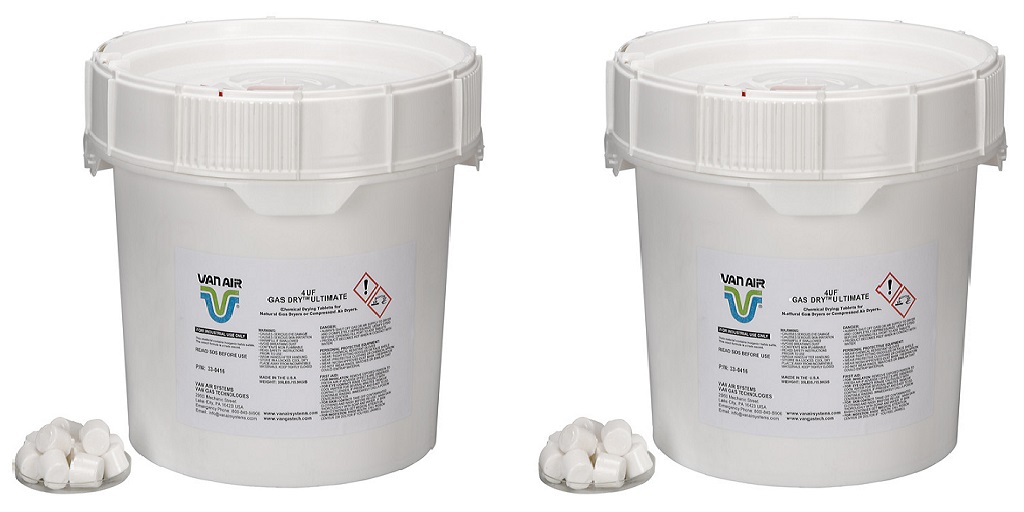

- Deliquescent Drying: A more passive method using tablets that absorb moisture and dissolve into brine. Ideal for lower flow rates or where electricity isn’t available.

In LNG facilities, where precision and reliability matter, PSA systems—especially explosion-proof models—are typically preferred for their capacity, consistency, and low dew point performance.

Where It Fits in the LNG Chain

A natural gas dehydration unit doesn’t only belong at the final liquefaction stage. In fact, it’s used in multiple spots across LNG infrastructure:

- Upstream Gas Gathering: To prep gas before compression and transport.

- Midstream Pipelines: To keep transmission lines free from corrosion and blockages.

- LNG Terminals: To condition instrument air and fuel gas within classified hazardous zones.

Explosion-proof regenerative dryers, like the HLSXG, are a smart solution for Class 1 Division 1 environments. These units deliver dew points down to -40°F, meet strict safety codes, and function reliably under harsh operating conditions. Their electrical systems are engineered to avoid spark generation—a must in volatile gas environments.

Efficient, Reliable, and Built for Harsh Settings

A key advantage of modern regenerative dehydration units is their ability to run continuously with minimal maintenance. With dual desiccant towers alternating between drying and regenerating cycles, they deliver dry gas around the clock—without needing operator intervention.

Also important is how these units manage purge gas. Instead of venting into the atmosphere, systems like the HLSXG route purge exhaust to a single coupling that connects to a vapor recovery unit or flare system, helping reduce emissions and improve site compliance.

And while glycol dehydrators have traditionally been used in gas processing, they come with drawbacks—fuel gas consumption, maintenance-heavy components, and emissions. In contrast, regenerative desiccant dryers are cleaner, quieter, and more cost-effective over the long term.

Supporting Systems in LNG Operations

Even in facilities that rely on molecular sieve systems for ultra-low dew point final-stage drying, regenerative natural gas dehydration units serve essential secondary roles. Whether it’s drying fuel gas to prevent flameout or conditioning pneumatic control systems, they provide operational stability at every level.

For LNG operators looking to future-proof their facilities, choosing the right natural gas dehydration unit means finding a system that balances safety, efficiency, and flexibility. Explosion-proof regenerative dryers like the HLSXG are purpose-built for these high-stakes environments.

To explore options designed for the LNG industry’s toughest demands, visit Air Vacuum & Process, Inc. to see what’s possible.