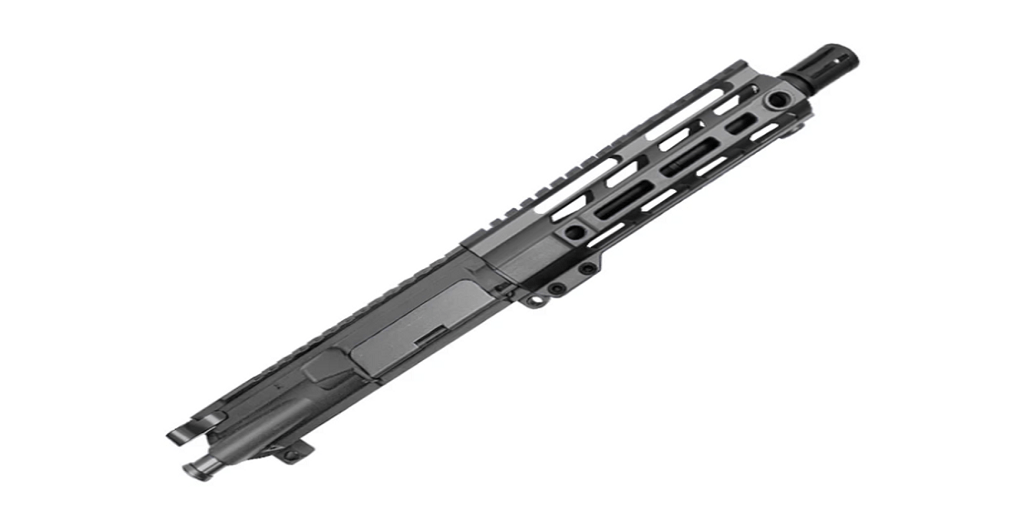

Take a look through any collection of assembled uppers. You will see that many of them come without BCGs, which means you’ll need to buy your own.

Be that as it may, no two BCGs are the same, and since the bolt carrier group is basically the heart of the rifle, it’s important to know a little about the different types of coatings that are commonly applied to them.

Phosphate, AKA Mil-Spec

Current mil-spec standards require a phosphate coating. This coating is more cost-effective than many of the others featured here, and phosphate-treated BCGs typically have chrome-lined gas keys.

Phosphate-coated BCGs also are non-reflective, which can be valuable in a combat zone. However, they have a bit of a tooth, which makes extra liquid lubrication necessary and can accelerate wear.

Hard Chrome

The first AR-15s were made with hard chrome BCGs, so if you want to go for a traditional look, outfit your AR-15 upper receiver with a hard chrome bolt carrier group. Hard chrome treatments are very durable, fairly hard, and easy to clean. However, they are more expensive than some treatments and do not exhibit the same permanent dry lubricity as other modern finishes.

Black Nitride

Black nitride (also known as Melonite) is a case-hardened, nitrogen-diffused surface treatment in which the aluminum of the BCG bonds with nitrogen.

Black nitrided BCGs are extremely hard and resistant to wear, corrosion, water damage, and scratching.

Black nitride also is extremely easy to clean and has very good permanent dry lubricity, so it requires less liquid lubrication to keep it running smoothly.

Titanium Nitride

Titanium nitride is a ceramic-style coating that results in an extremely hard, wear and corrosion resistant finish, just like black nitride. Also like black nitride, it requires less liquid lubrication because it has excellent permanent dry lubricity.

Another unique thing about titanium nitride treatments is that they have am attractive gold-tone finish, which some shooters appreciate. However, they have a fairly high price point.

Nickel Boron

At first glance, a nickel boron BCG might be mistaken for hard chrome, since they are both fairly bright, reflective silver.

However, nickel boron-coated BCGs are harder, more wear-resistant, and more corrosion-resistant. They also have an impressively low coefficient of friction, so they require less liquid lubricant.

All-around, nickel boron is an excellent BCG coating, but it can be very expensive.

Diamond-Like Carbon (DLC)

Diamond-like carbon, also known as DLC, is applied in a process known as physical vapor deposition, or PVD.

DLC coated BCGs are extremely hard, wear and corrosion-resistant, and have extremely low coefficients of friction. Because of the manner in which the coating is applied, they are effectively scratch, chip, peel, and flake-proof.

Also, like titanium nitride, it has an aesthetically pleasing appearance, except instead of gold it is a slick, graphite gray.

Thin-Film Ceramic

Thin-film ceramic coatings are made of nano-scale ceramic particles (which are extremely hard) suspended in a polymer binder.

When these are applied to a BCG and harden, they result in an exceptionally strong finish that is resistant to wear, corrosion, moisture, abrasion and scratching, chemicals, and in some cases, even ultraviolet light.

Thin-film ceramic coatings, like Cerakote, are hard, strong, resistant to impact, and thermal stress. Overall, they are very versatile, durable and long-lasting, though they don’t have the same permanent dry lubricity traits of some of the other finishes mentioned here.

Learn More About Assembled Uppers

Interested in learning more about assembled uppers and the parts you’ll need to complete a build at home or make repairs?

Visit MCS Gearup online at MCSGearup.com. They carry a wide range of assembled uppers as well as build kits along with piecemeal parts and hardware you’ll need to make upgrades, and repairs. Check out their online collection of complete uppers, parts kits, charging handles, gas systems, and more, and if you have any questions contact them at [email protected].