If you work in food service, hospitality, or packaging, you’ve probably seen “PE,” “HDPE,” “LDPE,” or “LLDPE” stamped somewhere or other on the packaging and containers you use.

Maybe you haven’t wondered what it meant. After all, you have a job to do and you probably aren’t going to let a tiny acronym ruin your workflow!

But may, just maybe, like the rest of us, you have wondered what it was and if it made any meaningful impact in the food service industry.

Well, it does.

You’ll notice that all of those monikers contain the letters “PE,” which stands for polyethylene. They are all grades of this particular plastic.

So, why is it used for food and drink packaging, and where can you get high-quality wholesale poly bags on rolls, poly tubing, and specialized gusseted food service containers made to a higher level of quality?

Why Polyethylene?

Polyethylene is a very commonly produced plastic, perhaps the most widely manufactured in the world. It is used to produce bags, films, bottles, and a wide range of other consumer goods. There is even furniture made from it!

In food service, packaging, and distribution, though, polyethylene is a vital, key component.

Commonly encountered as either LDPE or HDPE (see below) virgin polyethylene (meaning non-recycled) is considered food safe by the Food and Drug Administration and approved for direct food contact.

Most importantly, polyethylene does not leach harmful chemicals into the food, even on contact. This makes it safe for bottles, bags, film, and other materials used in food processing, packaging, and distribution.

Moreover, PE is resistant to chemical attack, resists the growth of mold and mildew, and repels many microorganisms. It’s also fairly strong, durable, and resistant to tearing, shearing and puncturing.

On top of these features that make polyethylene attractive to food packaging professionals, PE is also easily recyclable. It consumes fewer resources to recycle than many other plastic polymers, and it is often more affordable to recycle polyethylene than it is to produce more new PE from raw materials.

Consequently, many manufacturers, environmental scientists, and food service professionals consider PE not only safer for food packaging and handling but better for the environment as well.

HDPE vs. LDPE

The two most commonly encountered grades of polyethylene are HDPE, or high-density polyethylene, and LDPE, or low-density polyethylene. Both of these are used to make containers and packaging for food.

Despite the name, both forms of PE are actually very similar in density. HDPE is slightly denser, but it is its non-branching chemical structure that makes the difference.

HDPE, thanks to this molecular deviance, has a much higher tensile strength than LDPE. This makes HDPE the “PE of choice” for making rigid and semi-rigid containers like milk jugs, bottles, and containers.

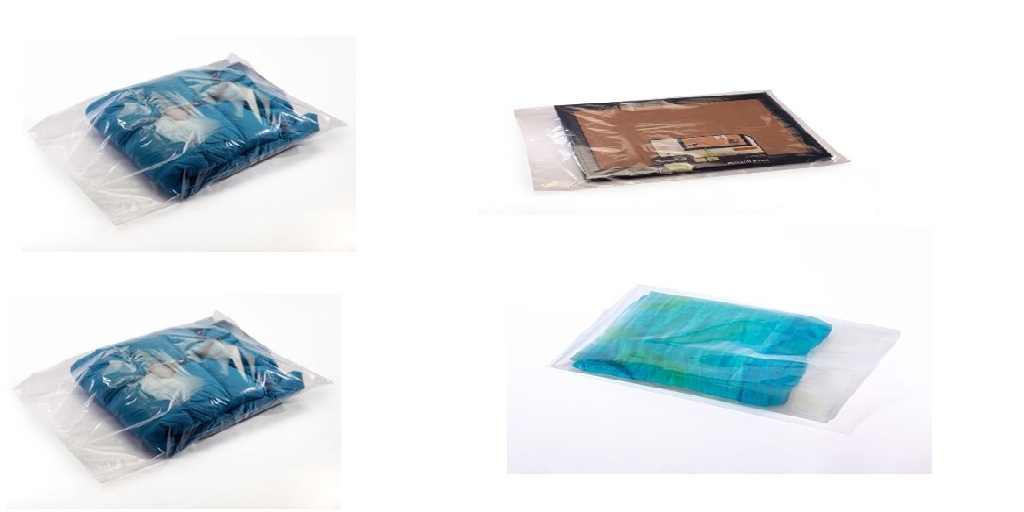

LDPE, which has a branched structure, is softer and stretchier than HDPE, which also allows it to remain flexible in colder temperatures. This makes LDPE more suitable for making films, bags, and liners than HDPE. Consequently, most if not all of the high-quality wholesale flat poly bags you encounter will be made from LDPE, or LLDPE (linear low-density polyethylene), a similar variant.

Where Can You Get High-Quality Wholesale Flat Poly Bags

Looking for high-quality wholesale flat poly bags? Look no farther than Edco Source, online at EdcoSource.com. They carry a wide variety of 100% virgin low-density polyethylene bag options in varying sizes and thicknesses that meet FDA and USDA specifications for direct food contact.

They also carry a commensurately wide range of other PE product packaging, such as lay flat poly bags (and twist ties), vegetable packaging, poly tubing, seafood bags, bakery bags, vacuum pouches, and much more.

To learn more about their diverse array of flat plastic bags and other packaging products, visit their website via the link above.